ň«óŠłĚ The Customer

Erling Sande ňůČňĆŞńŞ╗ŔŽüŔ┐ŤňĆúňĺîÚöÇňö«Ŕł╣ňƬŃÇüŔł╣ňƬňĺîŠĹęŠëśŔŻŽÚçîšÜäÚô⊝ĘňĆĹňŐĘŠť║ŃÇüŠáçŔç┤ŠĹęŠëśŔŻŽŃÇüň×üšîźÚŤ¬ňť░ŔŻŽňĺîŠ▓ÖŠ╗ęŔŻŽŃÇ銺ĄňĄľ´╝îńŞ║ń║ćŠëęň▒Ľń║žňôüŔîâňŤ┤´╝îňůČňĆŞŔ┐śÚöÇňö«ÚůŹňąŚÚÖäń╗ÂňĺîňĄçń╗ÂŃÇéŠîüš╗şňó×ÚĽ┐šÜäń║žňôüŠĽ░ÚçĆń┐âńŻ┐Ŕ»ąňůČňĆŞň╗║ÚÇኾ░ń╗ôň║ôň╣ÂÚ珚╗äňĚąńŻťŠÁüšĘőŃÇé

Erling Sande as is importing and distributing boats, Suzuki engines for boatsand motorbikes, Peugeot Scooters, Artic Cat snow mobiles and ATVÔÇÖs. In addition they sell accessories and spare parts to their broad product range. Continuousgrowth and in volume and number of products made it necessary to build a new warehouse and reorganize the working processes.

1 ń╗╗ňŐíň«Üń╣ë Task definition

šÄ░ŠťëšÜäń╗ôň║ôňĚ▓š╗ĆńŞŹŔâŻňĄčŠ╗íŔÂ│šëęŠÁüšÜäڝNJ▒éŃÇéňĄçń╗ÂňĺîÚůŹňąŚÚÖäń╗Âń╗Ä6000ňĄÜš▒│šÜäŔ┤žŠ×ÂńŞŐŠőúÚÇëňç║ŠŁą´╝îŔúůňůąŠëőŠÄĘŔŻŽŃÇéŔ┤žŠ×ÂňŹášöĘň╗║šşĹÚŁóšž»700ň╣│Šľ╣š▒│´╝îňéĘšëꚍĺńŞşňîůňÉźš║Ž38000ńެŔ┤žńŻŹ´╝îŠÇ╗ňů▒ňşśňéĘ45000ňĄÜńެńŞŹňÉîšÜäšëęňôüŃÇ銏«Ŕ«íš«Ś´╝îŠőúÚÇëŠÇžŔâŻńŞ║Š»Ćň░ĆŠŚÂ40Ŕ«óňŹĽŔíî´╝îňů▒ÚťÇńŞëń║║ň«îŠłÉŃÇéňůČňĆŞňŞîŠťŤŔŐéšťüšę║ÚŚ┤ŃÇüŠĆÉÚźśŠőúÚÇ늼łšÄç´╝îň«×šÄ░ň«×ŠŚÂň║ôňşśš«íšÉćŃÇüŠőúŔ┤žÚöÖŔ»»ŠťÇň░Ćňîľňĺîň░Ĺń║Ä24ň░ĆŠŚÂšÜäÚůŹÚÇüňçćňĄçŃÇé

Erling Sande as is importing and distributing boats, Suzuki engines for boats and motorbikes, Peugeot Scooters, Artic Cat snow mobiles and ATVÔÇÖs. In addition they sell accessories and spare parts to their broad product range. Continuousgrowth and in volume and number of products made it necessary to build a new warehouse and reorganize the working processes.

2 Ŕžúňć│Šľ╣Šíł Solution

ňťĘňŹáňť░ÚŁóšž»ńŞŹŔÂ│40 ň╣│š▒│šÜäšę║ÚŚ┤ňćůň«ëŔúůň×隍┤ňŤ×ŔŻČň╝Ćń╗ôňéĘš│╗š╗čŃÇé40 ´╝ůšÜäŔżâň░ĆÚâĘń╗ÂňşśŠöżňťĘ4 ňĆ░ Kardex Megamat RS 350Úçî´╝îŔ┐ÖňçáňĆ░Ŕ«żňĄçňÉźŠťëňĄÜšžŹň░║ň»ŞšÜäňéĘšëꚍĺŃÇéÚüÁňż¬ÔÇťňłćŠë╣ňĄäšÉćÔÇŁšÜäŠőúÚÇëňÄčňłÖ´╝îš╝ęščşŠőúŔ┤žŠŚÂÚŚ┤ŃÇéŠî皥║šü»´╝łTIC Matrix´╝늜żšĄ║šŤ«ŠáçňéĘšëꚍĺňĺ«Šáçň«╣ÚçĆ´╝îń╗ąńż┐ŠőúÚÇëňÖĘŔâŻňĄčň┐źÚÇčŃÇüšŤ┤ŠÄąŃÇüŠşúší«ňť░ňşśňĆľŔ┤žšëęŃÇéń╗ôň║ôš«íšÉćŔŻ»ń╗ÂńŻ┐šöĘŠë╣ÚçĆšž»š┤»šÜ䊾╣Š│ĽňÉŠĞňłÂ4ňĆ░Ŕ«żňĄç´╝îÚü┐ňůŹń║ćńŞĄńެŠőúÚÇëňÖĘšÜäšşëňżůŠŚÂÚŚ┤ŃÇé

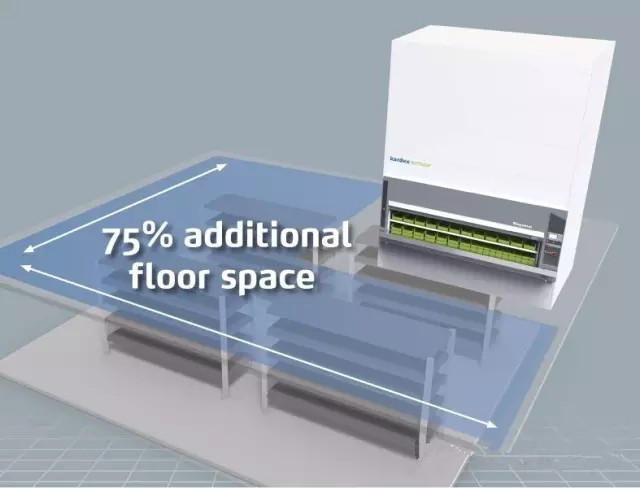

Vertical carousels were installed in less than 40 m2 floor space. 40 % of the smaller parts is accommodated in 4 Kardex Megamat RS 350, the units contains of bins of various sizes. Access times were achieved by using theÔÇťbatchÔÇŁ picking principle. A light indicator (TIC Matrix) shows the target bin and target volume to the picker to permit rapid, direct and error-free access.The warehouse management software used controls 4 machines simultaneously using batch accumulation. This avoids waiting times for the pickers.

3 Ŕ┐çšĘőŠĆĆŔ┐░ Process description

ŠłĹń╗ČňżłÚźśňů┤ń╗ąńެń║║ňĺĘŔ»óšÜ䊾╣ň╝ĆńŞ║ŠéĘŔ»Žš╗ćŔ«▓ŔžúŠÁüšĘőŃÇé

We would be delighted to explain the process description in detail in a personal consultation.

4 ń╝śňŐ┐ńŞÇŔžł

ÔÇôšŤŞňÉ░ÚçĆšÜäňĽćňôüňƬڝÇńŞŹňł░15´╝ůšÜäňŹáňť░ÚŁóšž»

ÔÇôńŻ┐šöĘÔÇťpick-by-lightÔÇť´╝î99´╝ůň«ëňůĘňşśňĆľ

ÔÇôšö▒ňÄčňůł1 / 3šÜäňĹśňĚąŠőúÚÇë´╝Ćň░ĆŠŚÂŔÂůŔ┐ç100ńެŔ«óňŹĽŔíî

ÔÇôŔŐéšťü70´╝ůšÜäń║║ňŐŤŔÁäŠ║É

4 Advantages at a glance

ÔÇô Same amount of goods on less than 15 % of the floor space

ÔÇô 99 % safe access by using ÔÇťpick-by-lightÔÇŁ operator prompting

ÔÇô More than 100 order lines per hour picked by 1/3 of the staff

ÔÇô 70 % less personnel resources

5 ńżŤŔ┤žŔîâňŤ┤

ÔÇô 4ňĆ░ň×隍┤ňŤ×ŔŻČň╝Ćń╗ôňéĘš│╗š╗č´╝îňů▒480ńެŠľÖŠ×Â

ÔÇô ňşśňéĘň«╣ÚçĆńŞ║8300ńެňéĘšëꚍĺ´╝î36500ńެŔ┤žńŻŹ

ÔÇô ň░║ň»Ş´╝Üň«Ż x ŠĚ▒ x Úźś ´╝Ü3475 x 1671 x 7960 Š»źš▒│

ÔÇô TIC Matrix ńŻŹšŻ«Šî皥║ňÖĘ

ÔÇô Power Pick Global ÔÇťOrder ProcessorÔÇťŔŻ»ń╗ +ňĆ»ÚÇë

ÔÇô ERPš│╗š╗č´╝łIBMŔžúňć│Šľ╣Šíł1´╝ëŠÄąňĆú

5 Scope of delivery

ÔÇô 4 vertical carousels with a total of 480 shelves

ÔÇô Storage capacity 8,300 containers, 36,500 locations

ÔÇô Dimensions W x D x H ´╝Ü3,475 x 1,671 x 7,960 mm

ÔÇô TIC Matrix position indicator

ÔÇô Power Pick Global ÔÇťOrder ProcessorÔÇŁ + Options

ÔÇô Interfaces to ERP system (IBM Solution 1)