Value Drug Mart 利用水平回转式仓储系统为供应链增值

Value Drug Mart Adds Value to the Supply Chain with Horizontal Carousels

在1978年,三家药店的所有者集中他们的采购和配送能力与大型供应链进行竞争,虽然当时仍然保持着独立的所有权并且开始依赖邻近地区的社会群体。 今天, Value Drug Mart旗下已经有32家成员股东店,也即是11家 Apple Drugs 商店, 8家 Rxellence 专业药店以及约300家附属店, 这些都由艾伯塔省埃德蒙特的中央配送中心服务提供服务。

In 1978, thirteen pharmacy owners centralized their purchasing and distribution power to compete with the big chains, while still maintaining the spirit of independent ownership and community focus that neighborhoods had come to depend on. Today, there are 32 member shareholder stores under the Value Drug Mart banner, as well as 11 Apple Drugs stores, 8 Rxellence Professional Dispensaries, and approximately 300 affiliated stores—all served by a central distribution center in Edmonton, Alberta.

Value Drug Mart 配送中心配送店面仓储货物(从床上用品和肥皂到连袜裤和唇膏等所有物品)以及药品; 在艾伯塔和大不列颠哥伦比亚地区保持着当地社区服务意识活跃和良好的传统。

The Value Drug Mart distribution center distributes front store items (everything from bedding and soap to pantyhose and chapstick) and pharmacy items; keeping the tradition of locally-owned, community-minded service alive and well throughout Alberta and British Columbia.

随着股东商店对其店面供应的扩大以保持竞争力, 也需要在他们的配送中心作出改变以更好地管理仓储空间。店面储存货物的订单快速地增长并且在几个店面存在对新增长的挑战。85000平方英尺的配送设施拥有60000平方英尺的仓库管理着分布在多个分拣区域的18000个库存单位,包括托盘货架,流动式货架,标准货架和大型货物区域。“我们的雇佣无法适应不断增长的需求,” 营运经理 Dwayne Bilawchuk 讲道。

With shareholder stores needing to expand their front store offerings to remain competitive, changes would also be required in their distribution center to better manage the cube. Orders for front store items were increasing rapidly and new growth presented challenges on several fronts. The 85,000 square foot distribution facility has a 60,000 square foot warehouse that manages 18,000 SKUs spread over multiple pick zones that included pallet rack, flow rack, standard shelving and bulk areas. “We couldn’t hire fast enough to keep up with the growing demand,” said Dwayne Bilawchuk, Operations Manager.

一个自动化解决方案

An Automated Solution

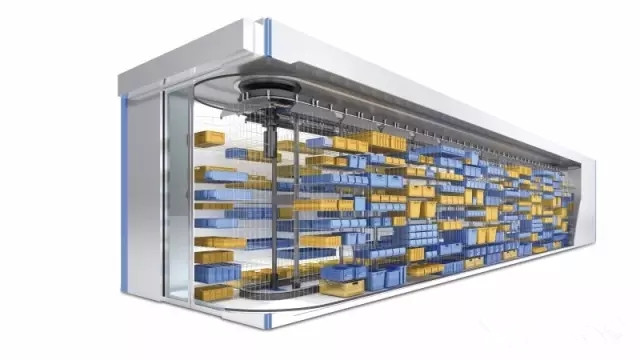

为了适应增长需求,Value Drug Mart 将两个静止货架替换成6台整合了按灯拣选技术的卡迪斯水平回转式仓储系统。水平回转式仓储系统被堆叠且排列成两个回转区域,每个区域带有8个位置进行成批作业。Bilawchuk已经额外增加了2个分拣位置,能够允许10个订单同时分拣,进一步增强了分拣生产率和订单吞吐量。

To meet increased demand, Value Drug Mart replaced two zones of static shelving with 6 horizontal carousels integrated with pick to light technology from Kardex Remstar. The horizontal carousels were stacked and arranged in two zones of 3 carousels, each zone with an 8 position batch. Bilawchuk has since added two additional picking positions, which would allow for 10 orders to be picked at atime, further increasing pick productivity and order through-put.

更快速的分拣…一切都加快了

Faster Picking… Much Faster

之前的货架包括有两个夹层,店面货物仓储在顶层,而药品在底层。这是一个无纸化分拣的环境。工作人员在拣货口分拣并使用遥控扫描器,在通道爬上爬下以执行订单分拣。软件用于提供分拣的逻辑顺序。“我们分拣得与员工一样快,货架与技术允许的情况下,仍然无法达到足够快的速度,”Bilawchuk讲道。

The previous shelving consisted of 2 levels of mezzanine, with front store items stored on the top level and pharmacy items on the bottom level. It was a paperless picking environment. Workers wore pickaprons and used remote scanners, traveling up and down aisles to fulfill orders. Software was in place to provide logical picking sequences. “We were picking as fast as staff, shelving and technology would permit, but it wasn’t fast enough,” said Bilawchuk.

所有位于两个货架区域的10000个库存单位向2个水平回转式仓储系统区域转移。底层的回转区域以350个订单线每小时的分拣速度管理着3100个店面库存单位。上层的回转区域以575个订单线每小时的速度管理者7100个药品库存单位。与之前以50个订单线每小时的货架速度相比,这两个区域将分拣速度平均加快了90%。

All 10,000 SKUs were moved from the 2 shelving zones into the 2 horizontal carousel zones. The lower carousel zone manages 3,100 front store SKUs with an average pick rate of 350 lines per hour.The upper carousel zone manages 7,100 pharmacy SKUs and boasts a pick rate of 575 lines per hour. With a previous pick rate of 50 lines per hour from shelving, these two zones are averaging a 90% faster pick rate!

减少劳工 Less Labor

这样的改变不仅使订单分拣加快,而且对劳工的需求也减少了70%。货架区域需要3名员工每天六小时管理每个区域。每个水平回转式仓储系统区域由一名员工轮流工作五小时。减少的两个区域人员小时总数从每天36小时到每天10小时用于分拣。

Not only are orders picked faster, but the labor required has been reduced by 72%. The shelving zones required 3 people for 6 hours per day to manage each zone. Each horizontal carousel zone is managed by 1 person working a 5 hour shift. Reducing the total number of man hours for both zones from 36 hours per day to 10 hours per day of picking.

空间 Space

之前的货架区域每层占用3900平方英尺。所有库存单位从夹层货架迁移进6台水平回转式仓储系统中,堆叠成2个区域。每个回转区域现在在每层占用1625平方英尺,节省2275平方英尺的地面空间—节省了58%的空间!重新空出的地面空间现在用于大型货物的仓储,大多数是之前被仓储在厂区外的位置。

The previous shelving zones occupied 3,900 square feet on each level. All SKUs were moved from the mezzanine shelving into the 6 horizontal carousels, stacked to create 2 zones. Each carousel zone now occupies 1,625 square feet on each level, saving 2,275 square feet of floor space- a 58% space savings! There covered floor space is now used for bulk goods storage, much of which was previously stored in an off site location.

精确扫描 Scanning For Accuracy

扫描器,类似于零售检查扫描器,被安装在每个成批作业工作站的末端。在每件货物被放进订单包裹之前都会被精确验证。在合并区域检查订单的精确性。“我们的订单精确度总是非常高,这项措施有助于我们维持接近完美的分拣精确度,”Bilawchuk讲道。

A scanner, similar to a retail check out scanner, is mounted at each end of the batch station. Before each item is placed in the order tote it is scanned for accuracy verification. The consolidation area spot checks orders for accuracy. “Our order accuracy has always been high, these measures help us maintain near perfect pick accuracy,”says Bilawchuk.

设备流程 Facility Flow

股东商店在一天内有多个订单。每家商店的订单在他们被送进仓库进行分配之前被合并为一个订单。这样使得配送中心按照商店进行订单分拣,但清单是根据多个订单进行安排。

Shareholder stores place several orders throughout the day. Orders for each store are consolidated into one order before they are sent through to the warehouse for fulfillment. This allows the distribution center to pick one order per store, but invoice it as the multiple orders that were placed.

配送中心被划分为28个区域(9个流动货架区域,5个大型货物分拣区域,12个货架区域和2个水平回转式仓储系统区域)。使用平行分拣策略,每个订单被划分进基于库存单位的订单指令。每个区域以该区域的库存单位进行订单执行并且将部分订单送至合并。

The distribution center is divided into 28 zones (9 flow rack zones, 5 bulk picking zones, 12 shelving zones and 2 horizontal carousel zones). Using a parallel picking strategy, each order is divided up among the zones based on the SKUs the order requires. Each zone fulfills the order with the SKUs from that zone and sends the partial order to consolidation.

在9个流动货架中的6个中的所有库存单位使用分拣和通道式策略进行分配。订单从一个分拣货架中进行分拣并通往下一个流动货架直至所有需要的库存单位拣选完毕。其他3个流动货架区域独立操作。如同其他区域,流动货架的库存单位被送至合并处与剩余的所需库存单位会合使订单得以完成。

All SKUs required from 6 of the 9 flow rack zones are filled using a pick and pass strategy. Orders are picked from one flow rack zone and passed to the next flow rack zone until all of the SKUs required are collected. The other three flow rack zones are processed independently. Like all other zones, the flow rack SKUs are then sent to consolidation to meet up with the rest of the required SKUs that will complete the order.

水平回转式仓储系统区域的订单所需库存单位的命令是从公司电脑主机界面进入的的Nova库存管理软件发出,其管理两个回转区域。水平回转式仓储系统的操作人员首先将装配包裹分配到批次作业工作站的位置上,每一个包裹代表一个订单。操作人员能够同时执行10个订单。按下按钮,3台回转系统旋转并检索至首个及其随后需要分拣的库存单位。

Orders requiring SKUs from the horizontal carousel zones are sent through an interface from the company host computer to the Nova inventory management software that manages both carousel zones. The horizontal carousel operator first assigns a shipping tote to a location on the batch station, each tote represents an order. The operator can fill up to 10 orders at one time. With the push of a button the 3 carousels spin to retrieve the first and subsequent SKU’s to be picked.

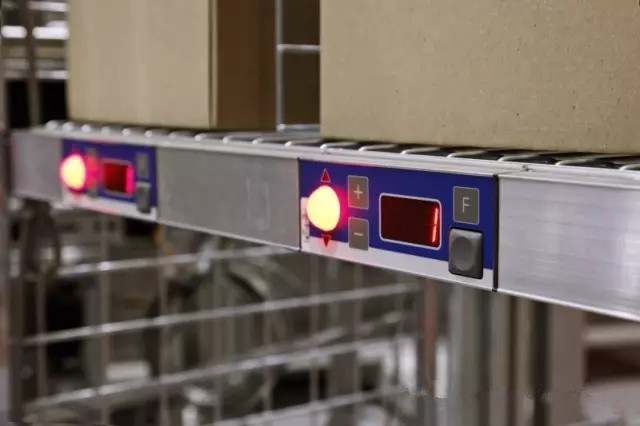

使用按灯拣选技术,操作人员被指示到水平回转式仓储系统中的精确单位进行分拣。灯光信号显示了需要分拣的数量。操作人员分拣其所需数量并将它们在位于成批作业工作台中的订单进行分配。

Using pick to light technology, the operator isdirected to the exact cell to pick from within the horizontal carousel. The light tower displays the quantity to pick. The operator picks the quantity required and turns to distribute them among the orders on the batch station.

在成批作业工作站中的每个位置也安装着固定的指示灯。这显示了放置到每个订单包裹的货物数量。在库存单位放置进包裹之前,操作人员使用安装在每个成批作业工作站末端的扫描器进行库存单位的精确扫描。当库存单位在订单中已分配完之后,操作人员按下确认按钮。

Each position on the batch station is also fitted with a put light. This displays the quantity to put into each order tote. Before placing the SKU into the tote, the operator scans the SKU for accuracy using the scanner mounted at each end of the batch station. When the SKUs have been distributed among the orders, the operator pushes a confirmation button.

当操作人员在订单中分配库存单位时,下一台水平回转式仓储系统已经自动定位至下一次分拣位,这样几乎消除了操作人员的等待时间。操作人员仅转身至三台水平回转式仓储系统并由按灯分拣技术指示进行下一次分拣。操作人员继续从回转系统中分拣并将订单中的库存单位进行分配直至每个订单中需要的所有库存单位都已被分拣完毕。

While the operator is distributing the SKUs among the orders, the next horizontal carousel has positioned itself for the next pick, virtually eliminating operator wait time. The operator simply turns back to the 3 horizontal carousels and the pick to light technology directs them to the next pick. The operator continues to pick from the carousels and distributethe SKUs among the orders until all SKUs for each order have been picked.

在每个水平回转式仓储系统区域完成的订单由传送器送至合并区,将其保留直至所有订单需要剩余的库存单位从其他区域送达合并处。一旦所有订单需要的的库存单位到达合并处,它们将被匹配并由传送器送至装运。

Completed orders are sent from each horizontal carousel zone via conveyor to the consolidation area where they are held until the rest of the SKUs required for the order arrive from other zones.Once all SKUs required for an order arrive at consolidation they are matched and forwarded via conveyor to shipping.

管理季节性增长

Managing Seasonal Growth

在秋季,Value Drug Mart 管理返校项目,给予学校预定儿童用品。Value Drug Mart为学校提供由学校供应的每个儿童订单。“在没有增加水平回转式仓储系统的条件下,我们无法扩展这项增长的季节性项目,” Bilawchuk讲道。

In the fall, Value Drug Mart manages a back to school program allowing schools to preorder supplies for children. Value Drug Mart provides the school one order per child with the supplies requested by the school. “This is a growing seasonal program that we would not have been able expand without the addition of the horizontal carousels,” said Bilawchuk.