快速,直接和可靠的操作,节省时间

Save time through rapid, direct and reliable access

Kardex Remstar 水平回转系统可用于任何需要快速,可靠和高效地仓储和分拣货物的地方。无论是在生产或分配上,对应用上要求的高出货量或中低速的运转:水平回转系统都是完美的解决方案。

The Kardex Remstar Horizontal Carousel is used everywhere where fast, reliable and cost-effcient storage and picking of goods is vital. Whether in production or distribution, for applications requiring high throughput or for medium and slow-movers: Horizontal Carousels are the perfect solution.

优势一览

– 高分拣性能和批量分拣,无等待时间

– 通过Pick-/Put-to-light技术达到精准分拣

– 7天/24小时全天候的可用性

Benefits at a Glance:

– High picking performance and no waiting times through batch picking

– High picking accuracy through Pick- and Put-to-Light technology

– 24/7 availability

更高的性能和快速的传送时间

For higher performance and fast delivery times

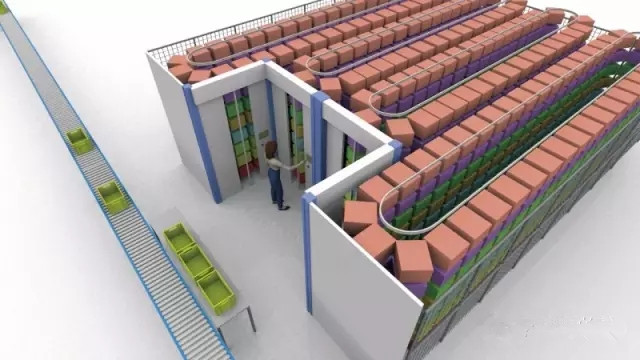

为了达到更高的分拣性能,水平回转系统通常与拣货站相结合。依据安装尺寸和构想,许多不同的排列方式都可能实现:

For higher picking performance, Horizontal Carousels are usually arranged in stations. Depending on the installation size and conception, a number of different layouts are possible:

二分式拣货站

Dual Station

L 型或 I 型(设备长度相同,并排放置)

L-shape or I-shape (all machines with same length arranged in line)

三分式和四分式拣货站

Triple and Quadruple stations

L 型或 I 型(所有设备长度相同,并排放置)或 U 型

L-shape or I-shape (all machines with same length; arranged in line) or U-shape

带升降台的高拣货站

Tall station with lifting platform

升降台在一个拣货区内完成完成所有货物的分拣之后才会移至下一个拣货区

Lifting plat form moves to all articles in one picking zone before moving to the next one

多层拣货站

Multi-level system

可选择性地安装输送技术,使物料能够在不同楼层之间流通

Conveyor technology can optionally be installed to allow material flow between the different levels

最佳分拣性能的九大优势

9 good reasons for optimum picking performance

Kardex Remstar 的成功准则: 优化您的生产率,提高吞吐量,减少空间需求,实现您仓库中的更高透明度。

Kardex Remstar’s formula for success: optimising your productivity and increasing your throughput while reducing space requirements and achieving greater transparency in your warehouse.

优势一:生产率

Benefit: Productivity

根据“货物到人”的原则,所需的货物被送至操作者,快速,直接和可靠,无任何多余传送和搜寻时间。对此,水平回转系统总是采取到达拣货口的最短径。工具显示面板为操作者显示了货物种类及其数量和分拣位置。

With the “goods to person“ principle, the requested items are transported to the operator – fast, directly and reliably – without any unproductive travel and search times. For that, the Horizontal Carousel always takes the shortest path to the access opening. The display-tool-feature shows the operator which goods and what quantities to pick from which storage location.

优势二:分拣性能

Benefit: Picking performance

在同时,独立运转的情况下,水平回转系统要比其他所有系统更加快速,拥有更高的分拣性能。在每个拣货站,一名操作者每小时能够完成200到400个位置上的分拣操作。在设备上和拣货站的光学显示屏使得其分拣精度超过99%。

Simultaneous, independent moving Horizontal Carousels of a station allow for a very fast overall system and high pick performance. One operator can work off 200 to 400 positions per station and hour. Optical displays on the machine and on the picking station allow for apick and put accuracy of over 99%.

优势三:批量分拣

Benefit: Batch picking

设备能够进行无纸化分拣,同时也能够打印传送票据和其他相关文件。通过电脑控制,仓库管理系统将多个订单整合进一个分拣批次中,因此操作者能够在减少走动的情况下分拣多个订单。

Paperless picking is possible while delivery notes and other relevant documents can continue to be printed. The warehouse management system combines several orders into a picking batch via PC control, allowing operator to pick multiple orders with reduced movements.

优势四:高载荷

Benefit: High payloads

水平回转系统能够对中小型货物进行完美的仓储和检索。此外,它能够仓储最大载荷为54吨的货物。载荷量可根据应用进行选择。

The Horizontal is ideally for storage and retrieval of small and medium sized items. Moreover it is capable of storing items with a maximum payload of 54 tons. The load capacity is chosen according to the application.

优势五:最佳空间利用

Benefit: Optimum space utilisation

货物被紧凑地仓储在有限的空间内;这样消除了在仓库内部多余的传送和分拣路径。实际的分拣区域缩小到5至10平方米。

Items are stored compactly in a confined space;this eliminates unproductive travel and picking routes within the warehouse. The actual picking zone is as small as 5 to 10 square meters.

优势六:可靠性和紧凑型设计

Benefit: Reliability and compact design

从发展,制造到对客户的服务:水平回转系统是紧凑,可靠,低维护成本的设备,其可用性接近100%,确保了设备的持续发展和长期的操作安全性。

From development, manufacturing to customer service: The Horizontal Carousel is a compact, reliable, low-maintenance unit with nearly 100 % availability – ensuring consistent and long term operational safety.

优势七:可变性

Benefit: Variability

为了在高峰时期达到高生产力并满足季节性分拣要求,在按下按钮时系统可分出不同的拣货站。因此,例如四台使用一个系统的水平回转系统不仅能够由一人操作,而且也能够由多人同时操作。

To achieve high throughput during peak times and meet seasonal picking requirements the system can be divided into different stations at the push of a button. Thus, it’s possible, for example, to have a system of four Horizontal Carousels operated not only by one person, but by several persons simultaneously.

优势八:安全性

Benefit: Safety

水平回转式仓储系统符合最高安全要求: 整台系统四周封闭并围有安全护栏,防止意外事故并同时避免未授权存取。此外,在设备前方的拣货口配备有自动开闭的安全门。

The Horizontal Carousels meet the highest safety requirements: The systems are closed all around and are surrounded by a safety fence which prevents accidents and protects from unauthorized access at the same time. Further more, the access opening on the station front side is equipped with safety doors that open and close automatically.

优势九:灵活性

Benefit:Flexibility

水平回转系统是适用于各种不同的应用和货物仓储。在托架方面,您可以选择特殊的货架间距并使其适应个别货物的仓储。.因此,设备能够对达到整个托架的高度的大体积货物进行高效仓储。

The Horizontal Carousel is suitable for a variety of different applications and items to be stored. Within the carriers, you can choose individual shelf distances and adapt them to the respective goods to bestored. Thus, even the effcient storage of bulky items is possible – up to the entire carrier height.